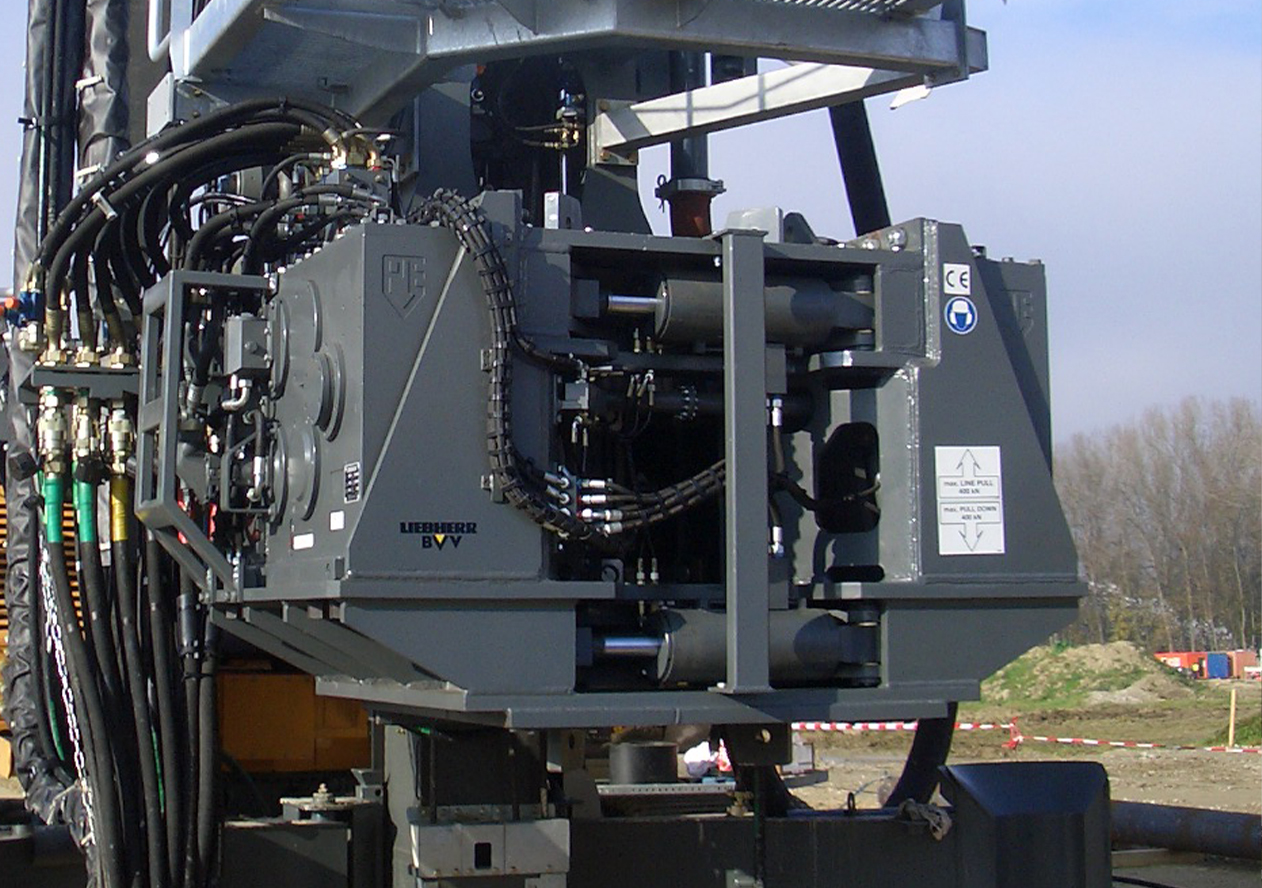

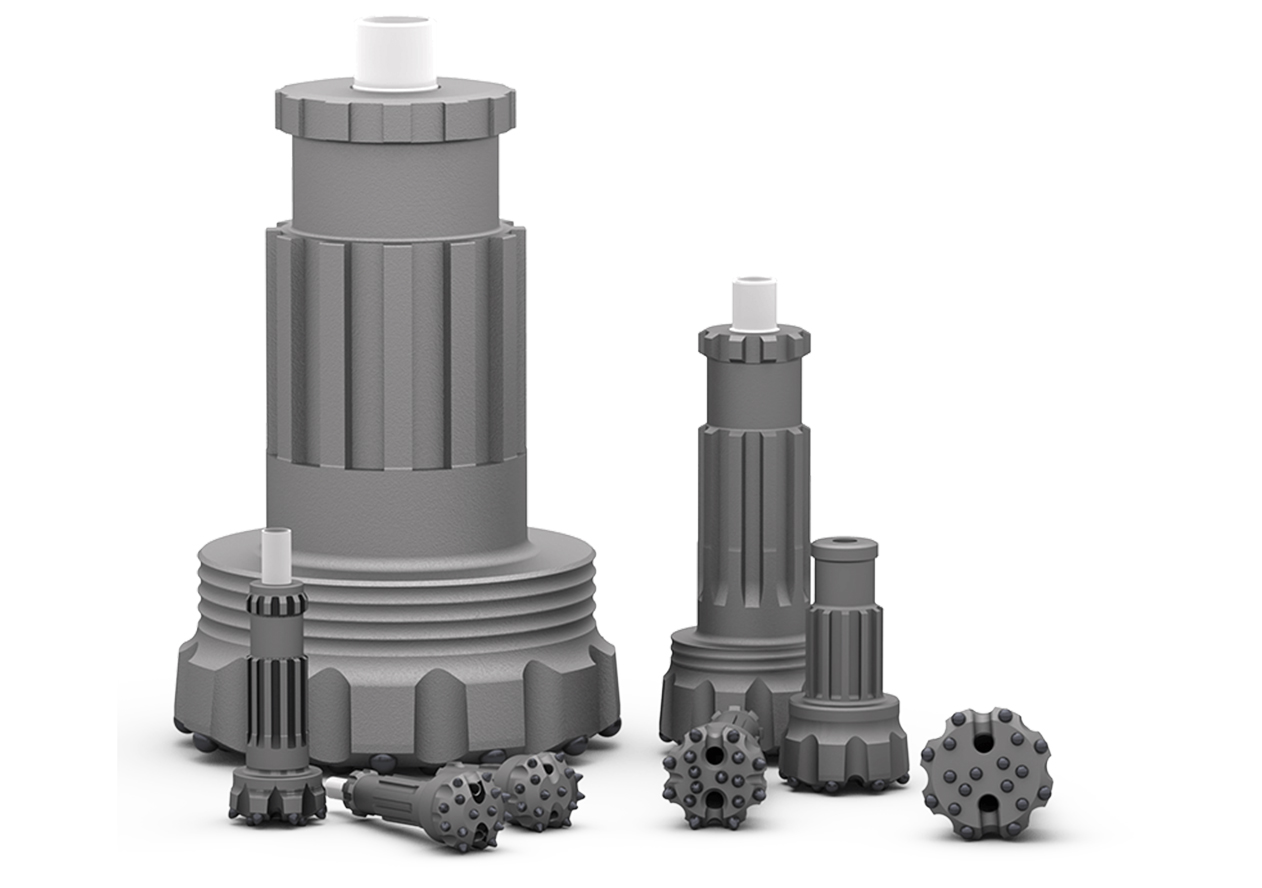

Mincon MP180N180 Hammer

The Mincon MP180 hammer has been designed to provide excellent drilling performance in all types of conditions while reducing the energy cost to do so. The tool can be used in all types of drilling applications and excels in simultaneous casing drilling for standalone piles and interlocked-casing drilling for pipe-pile walls.

Key Features and Benefits

- Patented features maximize energy output and reduce service requirements.

- Fewer internal components minimize service requirements.

- Valveless, high frequency design ensures smooth operation.

- Hardened wear sleeve for optimum wear resistance even in the most abrasive conditions.

- Multi-start threads on backhead and chuck ensure easy coupling/uncoupling of hammer.

- Unique internal mount system eliminates the need for wear shims and special assembly tools.

- All critical internal components are heat treated under strict control to maximize tool longevity.

For more information:

+40 314 253 800

info@romned.ro

Ron van Dam

CEO

| Description | Specifications |

| Hammer Outside Diameter | 400mm (15.75″) |

| Hammer Length (Backhead Shoulder Insert to Chuck) | 1708mm (67.2″) |

| Drill Bit Shank Type | N180 |

| Minimum Bit Size (rock) | 457mm (18″) |

| Minimum Bit Size (overburden) | 508mm (20″) |

| Hammer Weight (Less Bit) | 1209kg (2665 lbs) |

| Piston Weight | 282kg (622 lbs) |

| Backhead Stand Off | 0.3mm (0.012″) |

| Make up Torque | 18300 – 24400Nm (13500 – 18000 lbf.ft) |

| Wear Sleeve Reverse Limit | Not reversible |

| Wear Sleeve Discard Limit | 381mm (15″) |

| Recommended Minimum Air Package | 1038 l/s @ 13.8 bar (2200cfm @ 200psi) |

| Item # | Part Number | Description |

| MD1801AS01 | Mincon MP180-N180 (8 5/8″ A.P.I. Reg. Pin) | |

| 1 | MD1819BI01 | MP180 8 5/8 API Insert |

| 2 | MD1817BO06 | Backhead Insert Break out ring |

| 3 | MD1830CP01 | BH Tube Circlip |

| 4 | MD1816TB02 | Backhead Tube (8 5/8″ API Insert) |

| 5 | MD1823OR01 | O-Ring |

| 6 | MD1806CH01 | Choke Blank |

| 7 | MD1802CV01 | Check Valve |

| 8 | MD1803SP01 | Check Valve Spring |

| 9 | MD1801BH02 | Backhead For Adapter Insert |

| 10 | MD1817BO02 | Backhead Breakout Ring |

| 11 | MD1820OR01 | O-Ring |

| 12 | MD1821OR01 | O-Ring |

| 13 | MD1808IC01 | Inner Cylinder |

| 14 | MD1805LR01 | Lock Ring |

| 15 | MD1804SM01 | Make-up Ring |

| 16 | MD1812PR01 | IC Retaining Ring |

| 17 | MD1810PN01 | Piston |

| 18 | MD1811WS01 | Wear Sleeve |

| 19 | MD1812PR01 | Piston Retaining Ring |

| 20 | MD1813BB01 | Aligner |

| 21 | MD1822OR01 | O-Ring |

| 22 | MD1814BR01 | Bit Retaining Ring |

| 23 | MD1220OR01 | O-Ring |

| 24 | MD1817BO04 | Chuck Breakout Ring |

| 25 | MD1815CK01 | Chuck (N180) |

| 26 | MD1818CB01 | Chuck Bush |

| 27 | MD-N180DP | Drive Pin x 12 |

| MD1826SK01 | Service Kit | |

| 1 | MD1806CH01 | Choke Blank |

| 2 | MD1803SP01 | Spring |

| 3 | MD1825OK02 | O Ring Kit |

| 4 | MD1830CP01 | BH Tube Circlip |

| MD1825OK02 | O Ring Kit | |

| 1 | MD1820OR01 | O Ring |

| 2 | MD1821OR01 | O Ring |

| 3 | MD1822OR01 | O Ring |

| 4 | MD1220OR01 | O Ring |

| 5 | MD1823OR01 | O Ring |

| MD1841BD01 | Backhead/Distributor Assembly | |

| 1 | MD1801BH02 | Backhead For Adapter Insert |

| 2 | MD1807DR01 | Distributor Probe |

| MD1842PT01 | Piston Lifting Tool (Optional) | |

| MD1843HT01 | Hammer Lifting Tool (Optional) |

Air Pressures are given for compressors operating at seal level at 20° C (68º F). Corrections to actual compressor volume should be made to account for temperature, altitude and relative humidity.

- Hammers specifications

- Operation and Service Manual

- Parts and Specifications